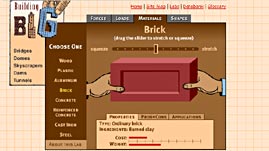

When humans first began building structures, they used only the natural materials available to them. The earliest builders constructed their dwellings, bridges, and dams from stone, mud, and wood. Over time, new materials were found or created. Concrete and brick provided good substitutes for stone, given that they could be made on site and molded into the desired shape. Iron and, later, steel provided builders with a versatile material that was resistant to both compression and tension.

Despite obvious innovations, however, materials technology has not evolved to the point where one material fits all building applications. Even steel, with its impressive strength and versatility, has limited usefulness in some structures, and stone and wood are still some of the most important building materials used today.

In the decision to use one material over another, engineers consider many factors. Among these, strength, weight, and cost are some of the most important considerations. Dams, for example, certainly rely on good design features to hold back the trillions of gallons of water some reservoirs contain, but more importantly, they rely on immense weight. This requires materials -- like concrete -- that are dense and, because of the large volume needed, relatively cheap. Except as support inside reinforced concrete, steel is generally too expensive to be used as dam material.

Other structures or parts of structures call for different types of materials. Aluminum alloys, for example, are resistant to corrosion, very light, and as strong or stronger than steel. Because of their high cost, however, these substances are typically used only in applications for which steel is less suitable, such as the outer covering, or skin, of skyscrapers.

Loading Standards

Loading Standards Teachers' Domain is proud to be a Pathways portal to the National Science Digital Library.

Teachers' Domain is proud to be a Pathways portal to the National Science Digital Library.