Teachers' Domain - Digital Media for the Classroom and Professional Development

User: Preview

Source: Montana State University

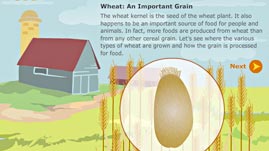

In this interactive activity adapted from Montana State University, view the wheat production process, from raw product to finished good. Learn about the structure of the wheat kernel, or seed, and how foods are made using ground kernels. The interactive activity also features a map of the United States, showing where specific wheat varieties are grown, and an animated demonstration of the process through which wheat is made into flour.

Cereal grains, which are the fruit seeds of different grasses, are used to produce a variety of foods consumed the world over. In their natural whole-grain form, cereal grains contain a rich supply of nutrients, including vitamins, minerals, oils, and proteins. According to the United Nations' Food and Agriculture Organization (2008 statistics), of all the cereal grains grown, wheat is the second-largest crop type by weight, after corn and just ahead of rice. Although more corn is produced by weight, more foods are produced from wheat than from any other cereal grain.

As the interactive activity explains, wheat grain is used primarily to produce flour, which is the main ingredient of bread, crackers, cakes, cookies, and pasta. Secondary products of wheat grain processing are bran, which is found in breakfast cereals, and "shorts," which are used to feed livestock. Besides these food products, wheat grain can also be fermented to produce alcohol and even biofuels, the term given to renewable fuels derived from living biological matter.

Modern farming uses automation and technology to generate larger-scale production with greater efficiency. In accomplishing this, corporate and small family farms alike can offer lower-cost products to the global marketplace. Among modern farming's tools are high-tech machinery and cutting-edge agricultural practices that include chemical applications that better protect crop plants from disease, drought, and pests; crossbreeding techniques; and genetic engineering. This approach to agriculture has dramatically increased yields, first in developed nations, and more recently in developing countries as technologies and know-how have been exported. Beyond making these productivity gains, today's farmers and plant scientists have also managed to improve taste and nutritional content.

Modern techniques have extended from the fields to the facilities in which wheat is processed into flour. In automated plants, where equipment is run by software rather than by individual laborers, hands-free systems may operate in all areas, including where the wheat is brought in, where it gets blended and cleaned, and where it is milled and then routed for packaging. Automation can reduce the amount of paid labor needed to run a plant. But there are other benefits for the owners of these facilities. The software-based systems are extremely accurate and reliable, so that raw materials and any additives are not wasted and the protein levels in the final product can be carefully monitored and controlled.

Loading Standards

Loading Standards Teachers' Domain is proud to be a Pathways portal to the National Science Digital Library.

Teachers' Domain is proud to be a Pathways portal to the National Science Digital Library.